Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

2021-09-24

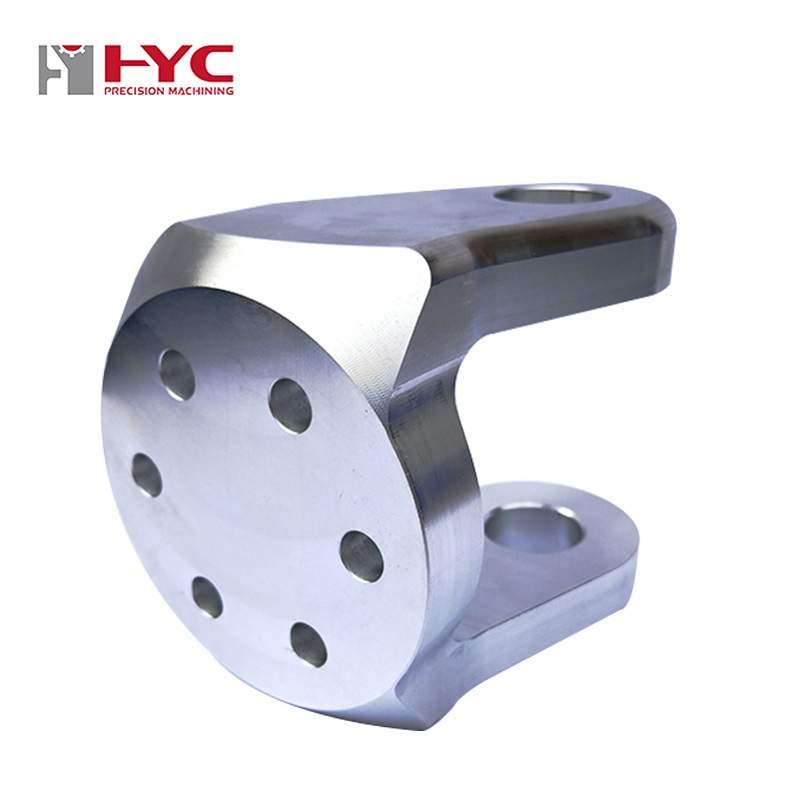

CNC machining material selection is more than 3D printing, general hardware and plastic plates can be CNC machining, and the density of molding parts is better than 3D printing.

2. Parts differences caused by the forming principle, 3D printing is an additive manufacturing. Its principle is to cut the model into N layers /N points, and then pile up layer by layer in sequence/bit by bit, just like building blocks. Therefore, 3D printing can effectively process and produce parts with complex structure, such as hollow parts, while CNC is difficult to achieve hollow parts processing.

3. Differences in operating software

4. Differences in post-processing 3D printing parts post-processing options are few, generally grinding, oil spraying, deburring, dyeing and so on. And CNC Machining Parts post-processing options are varied, in addition to grinding, oil spraying, deburring, electroplating, screen printing, pad printing, metal oxidation, radium carving, sandblasting and so on. Listen to the way has successively, the skill profession has specialized. CNC machining and 3D printing each have their own advantages and disadvantages. Choosing the right processing technology plays a vital role in your hand plate project.

Share to:

Send Inquiry

Mr. Zou

Tel:86--15013568605

Fax:

Mobile Phone:+8615013568605

Email:zou@hycmetal.com

Address:Shop 26-27, Commercial Street, Niutou Village, Niushan Village Committee, Dongcheng District, Dongguan, Guangdong

Related Products List

Mobile Site

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.