Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

2022-01-04

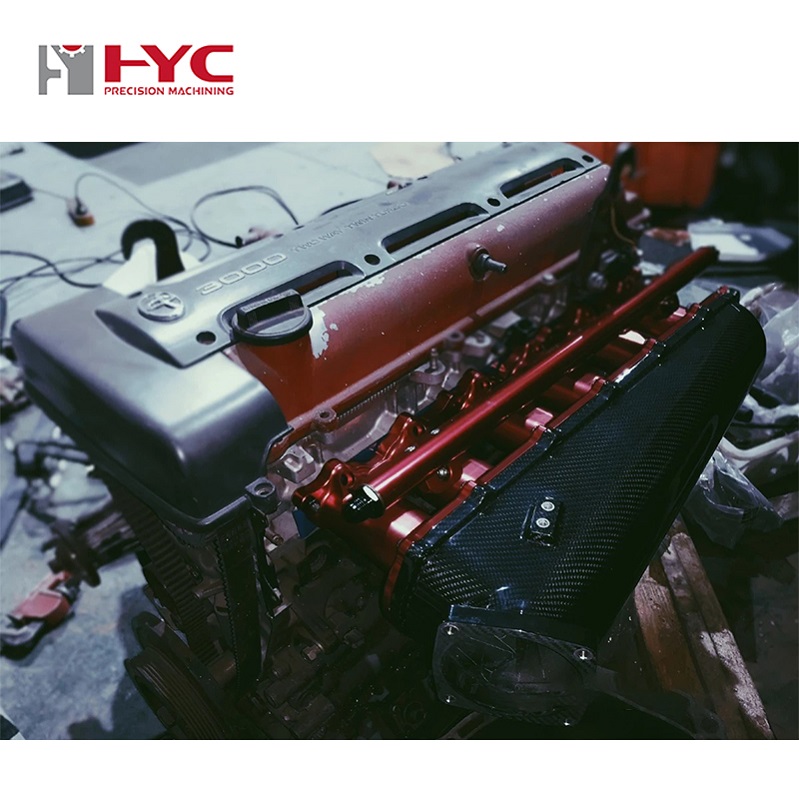

CNC machining is the preferred manufacturing method for engineers in the automotive industry. When designing custom car parts, it is important to have a variety of materials to choose from, as well as a variety of custom finish options. In the factory, automotive production engineers are using FDM's large-scale manufacturing to specifically manufacture assembly jigs and fixtures up to three feet in length!

Share to:

Send Inquiry

Mr. Zou

Tel:86--15013568605

Fax:

Mobile Phone:+8615013568605

Email:zou@hycmetal.com

Address:Shop 26-27, Commercial Street, Niutou Village, Niushan Village Committee, Dongcheng District, Dongguan, Guangdong

Related Products List

Mobile Site

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.