Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Products

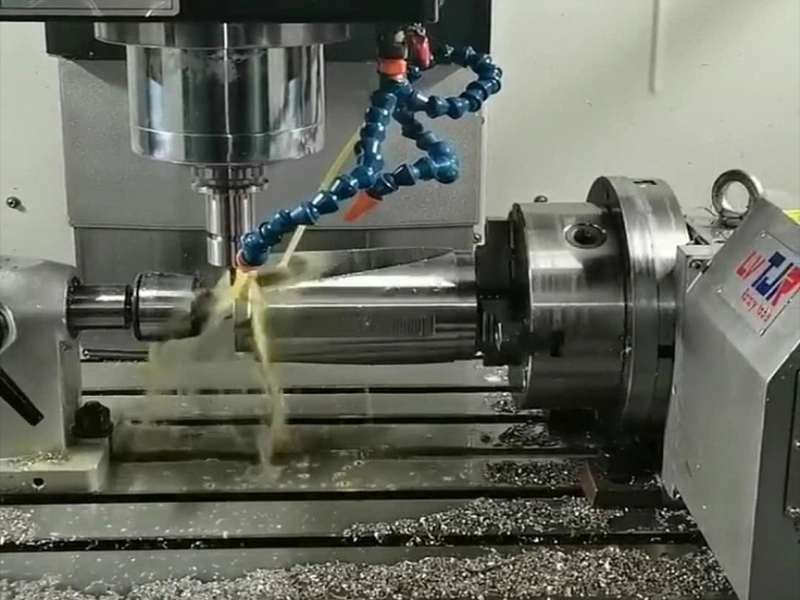

Advanced equipment and standard production management system are one of our advantages. Our equipment can be mechanized and automatically produced 24 hours a day, which greatly improves production efficiency and reduces human errors. Our production workshop is also very bright and clean, so the quality of the products produced is very good. In addition, we also have a unique core technology, which can further guarantee the quality of your products. The parts produced by us have the characteristics of high density, not easy to deform, not easy to break, and stable quality. In addition, our reliable after-sales service can give you more peace of mind and worry-free use of our products throughout the process.

We provide services for Custom Metal Working, Steel Fabrication Service and Machining of Parts, if you are intrested, please contact us.

Our main products:Cnc Turning Parts,CNC Machining Parts,Gear Cutting,Lighting Accessories,Precision grinding parts,Hardware Parts

Product Categories : Precision Grinding Parts > Precision Steel Parts

Our machining shop was founded in 2016, The company specializes in providing customized parts services, covering : automotive, automation equipment, medical equipment, electronic equipment, outdoor sporting goods, communications industry, Marine equipment, aviation flight, photography equipment. Production equipment of our factory : CNC machining center, CNC lathe, CNC drilling machines, 3 axis CNC machines, 4 axis CNC machines, CNC milling and turning machines, precision grinder, milling machines, tapping machines,Our team is composed of 15-25 engineers, among them more than 12 years experience in precision parts processing, they skillfully use processing software, UG, MASTERCAM, SOLIDWORKS, CAD, CNC programmers according to the customer to provide 3 d model, through the software simulation on the process, optimizing the processing programming and manufacturing process, improve production efficiency, saving the cost of spare parts for our customers.

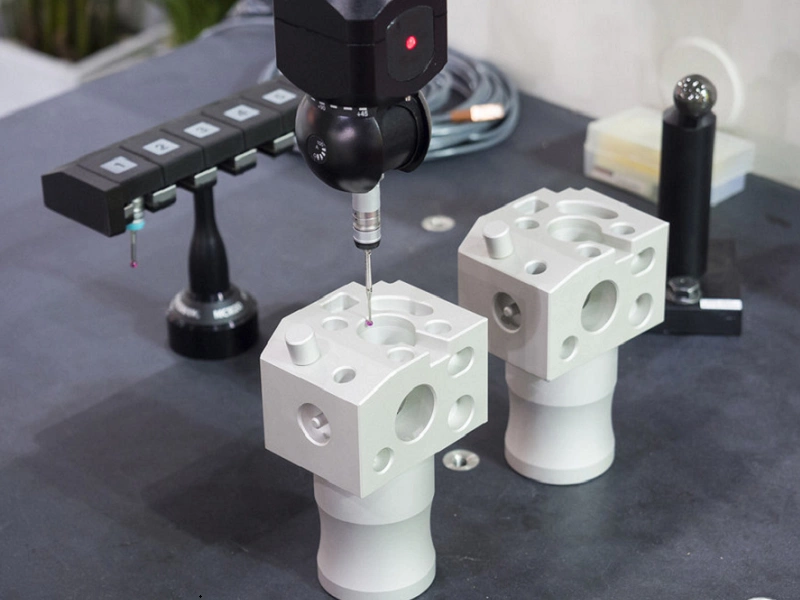

We have strict quality control and require manufacturing engineers to self-check the important dimensions of parts during the process. The quality inspector checks every dimension of the parts according to the drawing to ensure that all parts delivered to the customer are qualified.

We small businesses have big dreams. We adhere to the quality and service as the first development concept, strengthen enterprise management, continuous investment in intelligent manufacturing, we strictly confidential customers' design drawings and documents, regular destruction of drawings. After 4 years of development, we have accumulated more than ten customers, they are from: the United States, Canada, Australia, France, Germany, Netherlands, they benefit from our OEM services.

Machining type : Cnc Machining Parts, Precision Grinding Parts, CNC Turning Parts, Milling parts, 4 Axis machining parts, custom parts, complex parts.

Machining tolerance : Cnc Machining +- 0.005MM,Precision Grinding 0.002MM,Test tolerance: 0.001MM

Part size range : Cnc Machining 1000x800x400MM, CNC Turning diameter 400MM

Materials: aluminum, steel, stainless steel, brass, plastic.

Aluminium alloy :AL6061-T6,AL7075-T6,5052,2A12,1050,1060,1100,2024,5083,6082,2014,2017

Steel :20#,45#,1080, carbon steel, tool steel, 136, die steel, Skd11.

stainless steel:17-4ph,SUS201,SUS303,SUS304,SUS316,SUS420,

Parts surface treatment: polishing, sandblasting, hard anodizing, Color anodizing : Gold, black, gray, red, blue, green, purple

Electroplating:Nickel, zinc, chromium, gold, silver,teflon.

Home > Products > Precision Grinding Parts > Precision Steel Parts > Professional OEM Service Custom Stainless Steel Machining

Send Inquiry

Mr. Zou

Tel:86--15013568605

Fax:

Mobile Phone:+8615013568605

Email:zou@hycmetal.com

Address:Shop 26-27, Commercial Street, Niutou Village, Niushan Village Committee, Dongcheng District, Dongguan, Guangdong

Related Products List

Mobile Site

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.