The applicable processing range of the processing center: Machining centers can be used in all major industries, especially the focus industries that a few countries are facing. The machining center mainly processes box-shaped workpieces, complex surface-type workpieces, special-shaped workpieces, disk-type workpieces, sleeve-type workpieces, plate-type workpieces and other complex style workpieces, which can be processed by the machining center. The machining center is an intensive multi-process processing equipment, so it can realize multi-process processing for the processing and clamping at one time, and can process workpieces with complex center styles, multiple processes, and relatively high precision requirements. The machining center can also be upgraded to a multi-axis machining center, which can expand the processing range, and can realize the processing of multiple faces of the workpiece at one time. Therefore, the processing range of the machining center is very broad. Let's take a look at what types of parts and molds the machining center can process.

Machining complex curved workpieces: Ordinary machining of complex curved workpieces is a machining center that uses more than four-axis linkage. For example, a five-axis machining center can process various complex curved workpieces. A three-axis machining center can also be used for simple curved workpieces, but a ball-end milling cutter must be used for three-axis machining. Coordinates are used to realize processing, and the processing obedience is high, but the obedience is relatively low. Complex curved workpieces cannot be processed by the three-axis machining center, because the three-axis machining center can only process simple curved workpieces, while complex curved workpieces cannot be processed. For example, impellers, blades, marine propellers and other complex curved parts require five Only axis linkage machining center can realize machining.

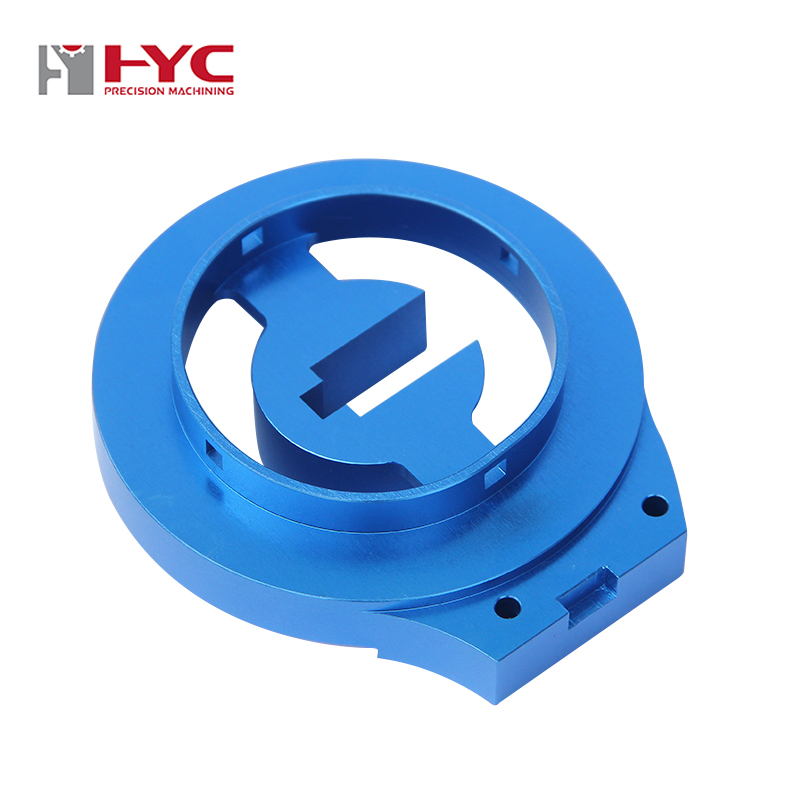

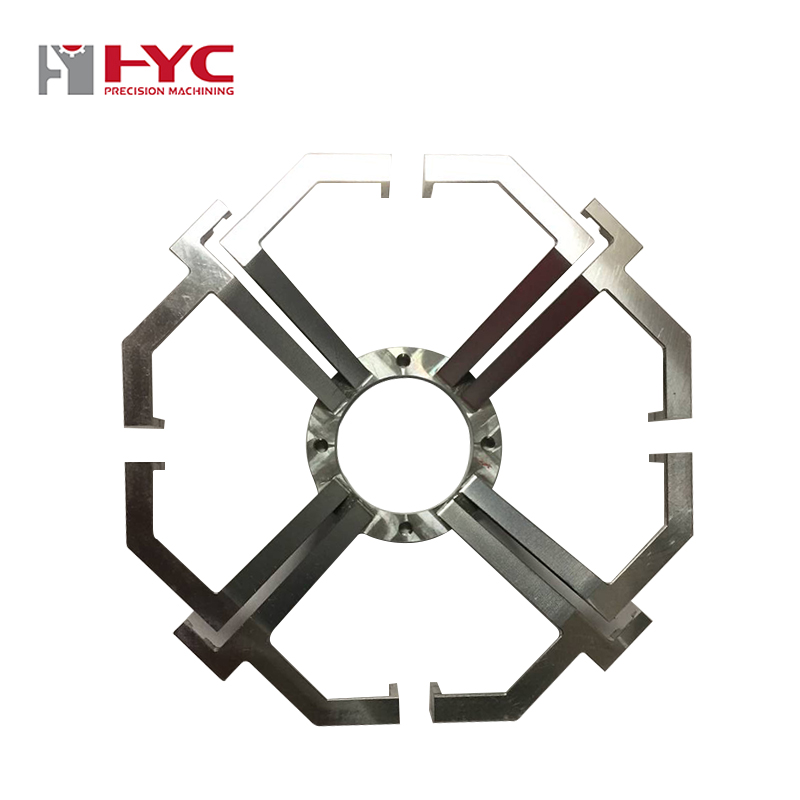

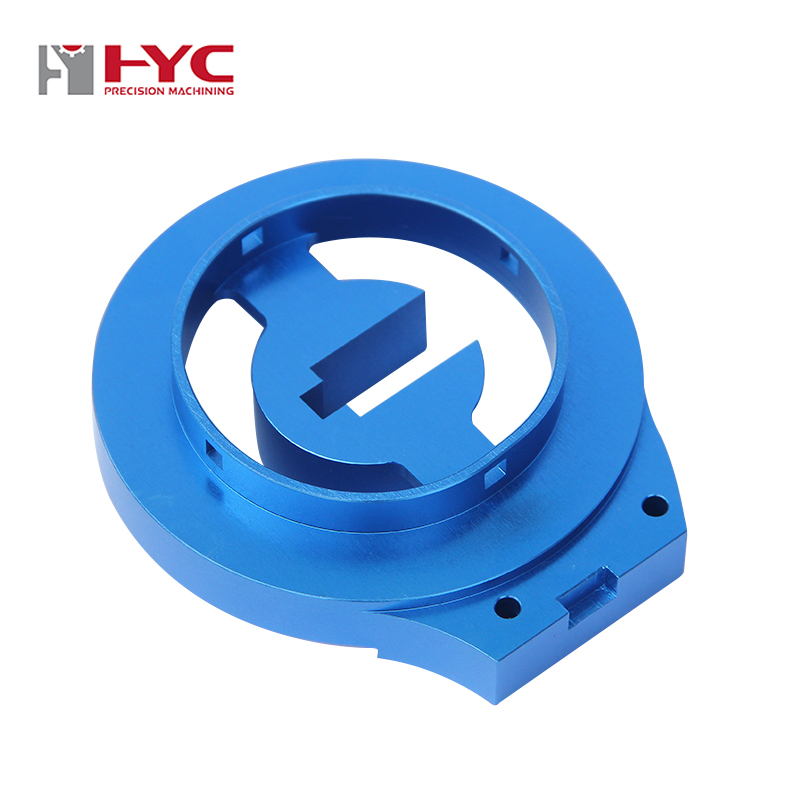

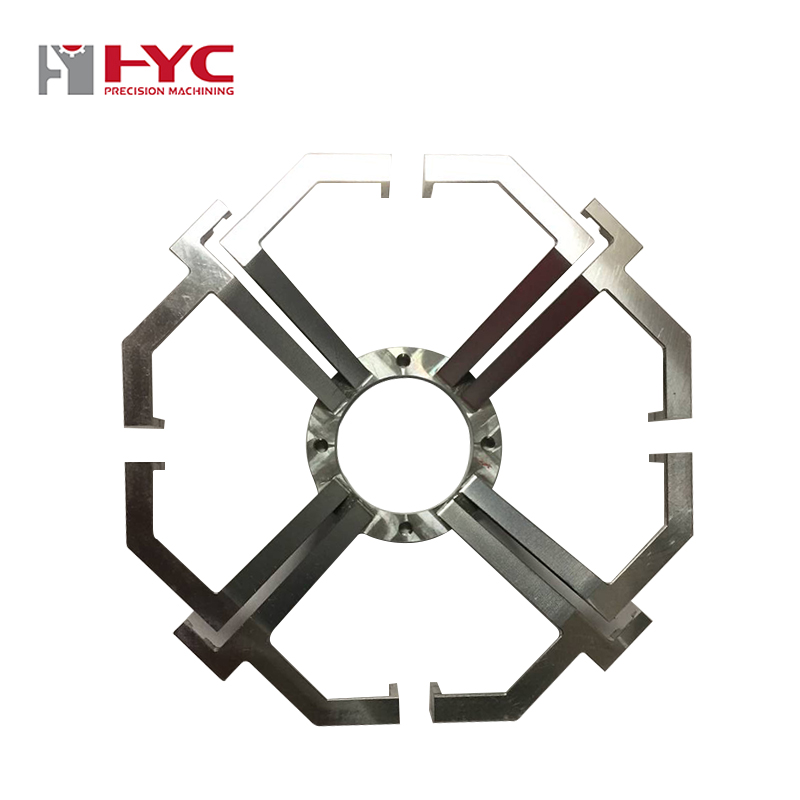

Processing box-like workpieces: Machining center machining center box type workpieces are generally processed with high precision holes and planes. When machining center processing box type workpieces, one clamping can achieve 60% to 95% of the processing procedures. Processing special-shaped workpieces: What is a special-shaped workpiece? The special-shaped part is a part composed of a mixture of points, lines and surfaces. Its shape is very strange and irregular. The processing of this type of workpiece needs to be applied to the five-axis linkage machining center, and the processing of special-shaped parts is, the more the style is Complicated, the higher the precision requirements, the more the superiority of the machining center appears. Such as brackets and so on. Workpieces such as discs, sleeves and plates: There are many such workpieces, including sleeves with keyways and radial holes, flat relative porous systems, curved surfaces, and shaft parts, such as flanged shaft sleeves, shaft parts with keyways or square heads, etc. , Plate parts with porous processing, such as various motor covers and the like.