Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

2022-12-26

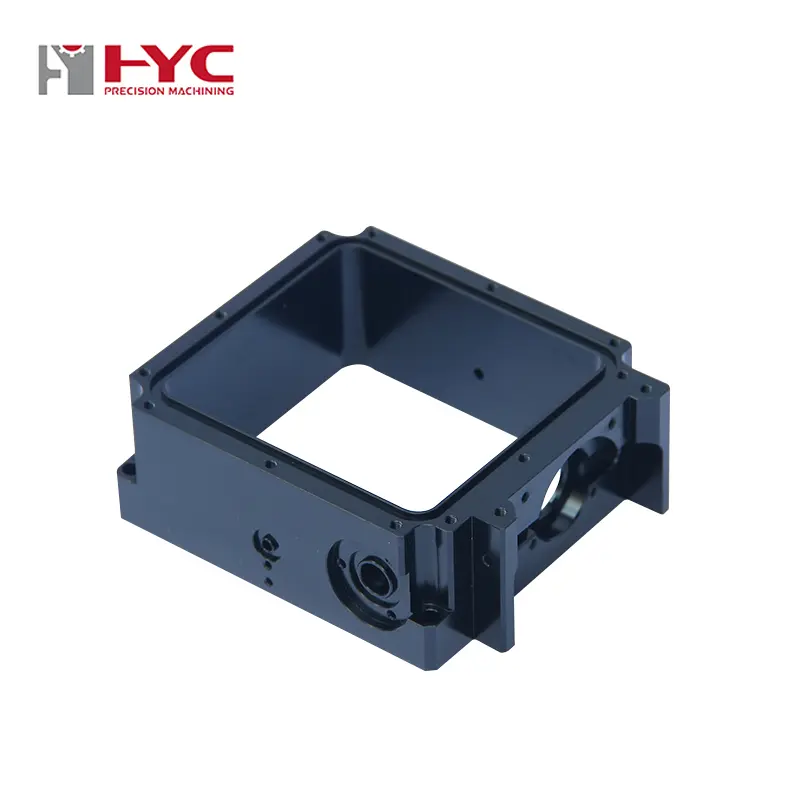

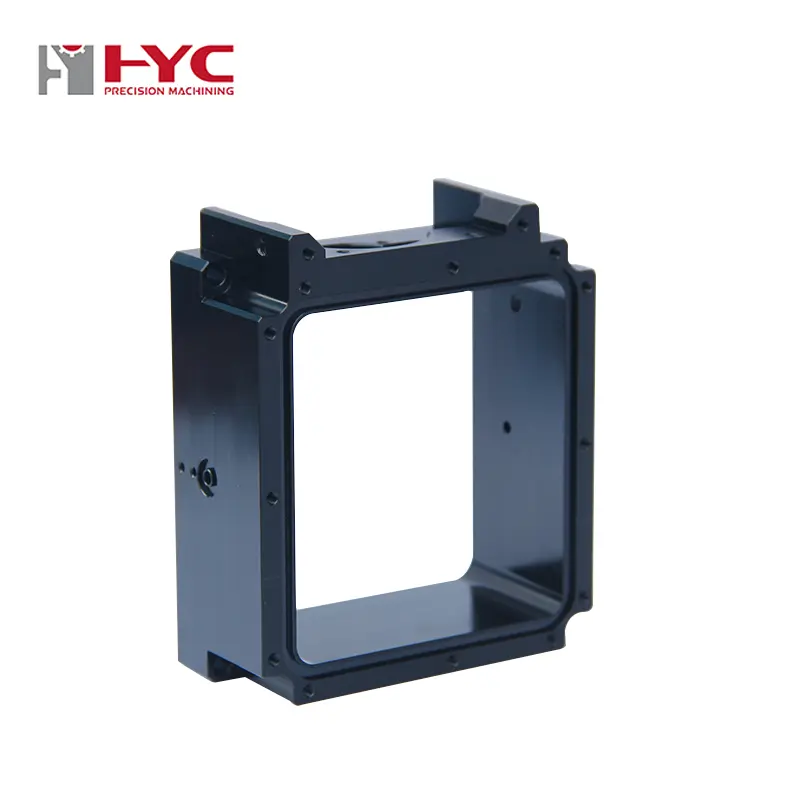

Shaft parts in machine products are general-purpose parts and are widely used. The working ability and quality of the machine are largely related to the shaft. Once the shaft fails, it may cause serious consequences. The shaft is one of the important parts that make up the mechanical structure. For the processing of shaft parts, look for Hua Evonik. It is the main part of the shaft system parts, and it is also the key component that supports the parts on the shaft and transmits motion and power. In order to ensure that the parts installed on the shaft can be correctly positioned and fixed to meet the requirements of machining and assembly of the shaft, the shape and structural dimensions of each part of the shaft must be reasonably determined, that is, the structural design. Our products include 4 Axis Machining parts , 5 Axis Machining Parts.

Secondly, determine its possible failure mode according to its bearing type and working condition, and then select the corresponding design criteria for performance design. Shaft performance design criteria include strength criteria and stiffness criteria. High-speed shafts often require vibration stability design. The main purpose of shaft vibration stability design is to avoid excessive shaft vibration, especially resonance. The precision design of the shaft, including its dimensional and geometric tolerances.

Share to:

Send Inquiry

Mr. Zou

Tel:86--15013568605

Fax:

Mobile Phone:+8615013568605

Email:zou@hycmetal.com

Address:Shop 26-27, Commercial Street, Niutou Village, Niushan Village Committee, Dongcheng District, Dongguan, Guangdong

Related Products List

Mobile Site

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.